NEXT-GEN INFRARED POLARIZERS

Coherent employs meta-optics technology to achieve a breakthrough in infrared polarizers.

February 13, 2024 by Coherent

Leveraging decades of experience in infrared optics and our latest advancements in meta-optics and nanopatterning, Coherent has created a revolutionary family of infrared polarizers that deliver unprecedented performance and reliability. These will improve outcomes in a variety of mid-wavelength infrared (MWIR) and long-wavelength infrared (LWIR) applications such as atmospheric remote sensing based on quantum cascade lasers, (QCL), infrared machine vision systems, forward-looking infrared (FLIR) imagers, and even astronomy.

The Challenge of IR Polarizers

Polarizers are a widely used component in all sorts of optical systems, and especially with lasers. There are several different technologies in use for making polarizers. These work quite well with visible and near-infrared light.

But, making polarizers for longer wavelengths, like the MWIR (3 µm – 5 µm) and LWIR (7 µm – 14 µm) spectral ranges has long presented challenges. This is especially true for polarizers based on thin film (coating) technology. The reason is because the optical characteristics and costs of infrared transmissive materials don’t readily permit economical construction of polarizers with the same levels of performance and reliability as their shorter-wavelength counterparts. These issues become more pronounced for LWIR devices because silicon, the most commonly used beamsplitter substrate material, doesn’t transmit well above 6 µm.

To avoid the limitations of thin film devices, the traditional solution has been the ‘wire grid’ polarizer (WGP). The WGP consists of a series of parallel, electrically conductive structures (e.g. metal wires) on a flat, transmissive substrate. The separation between wires must be smaller than the wavelength of the light, and the width of each wire must be much smaller than the separation between its neighbors.

Incoming light polarized in the long direction of the wires induces electrons to move freely along their length. This makes the wire array act like a traditional metallic-coated mirror, and the light is reflected.

If incoming light is polarized perpendicular to the wires, then the electrons can’t move very far due to the narrow width of the conductors. As a result, little or no current is produced. This frustrates the reflection and allows most of the light to pass through.

A wire grid polarizer contains an array of conductive stripes. Light which is polarized parallel to the stripes – which means that its electric field oscillates in their long direction – induces a current within them. This causes the light to be reflected. The narrow width of the stripes prevents any significant current flow in that direction, so light polarized perpendicular to the stripes induces no current and simply passes through.

Wire Coherent Polarizers Better?

But WGPs have had their own set of problems. A major issue is that aluminum is usually used as the wire material. But, aluminum oxidizes, especially when exposed to higher temperatures, and this lowers the performance of the polarizer. Even placing a protective layer over the wires fails to prevent this oxidation from occurring. And both copper and silver, which are less commonly employed for this application, suffer from the same disadvantage.

Coherent has applied a number of technological advances to overcome the drawbacks of these legacy devices. First, we’ve switched to using a different, inert metal for the wires that doesn’t oxidize. This extends device lifetime and reliability, especially when exposed to high temperatures and humidities.

Next, we have applied our decades of experience in the production of meta-optic surfaces to produce a better wire structure. Our advanced photolithographic methods enable us to control the morphology of the wires more precisely to improve overall optical performance of the WGP. Specifically, this includes increasing the polarizer’s extinction ratio (a measure of how well the optic passes the desired polarization and rejects the undesired one). Our technology also permits us to highly optimize performance for a specific wavelength or wavelength range. And it delivers higher unit-to-unit consistency in volume production.

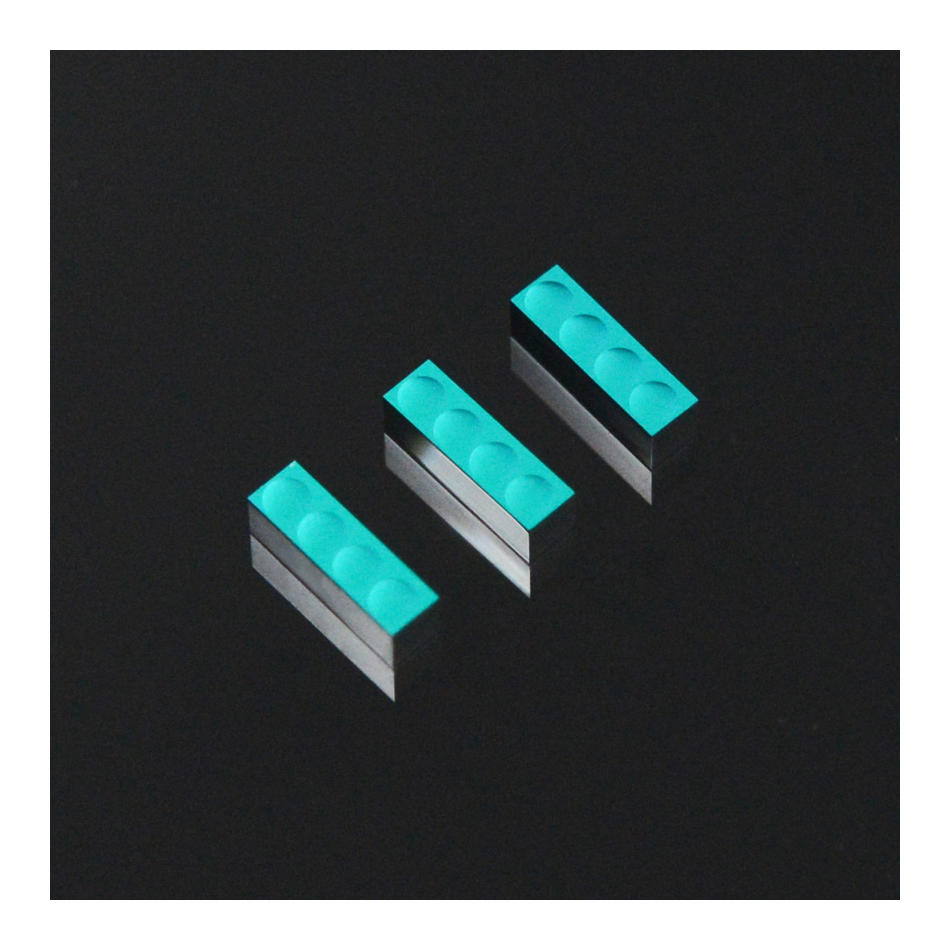

Coherent wire grid polarizers on silicon substrate.

Our capabilities in materials and thin film antireflection coatings also come into play, especially for LWIR polarizers. For this spectral range, we use ZnS, rather than silicon as the substrate material. While others use ZnS, too, we’re able to get superior results when combining this material with our nano-lithographic technology.

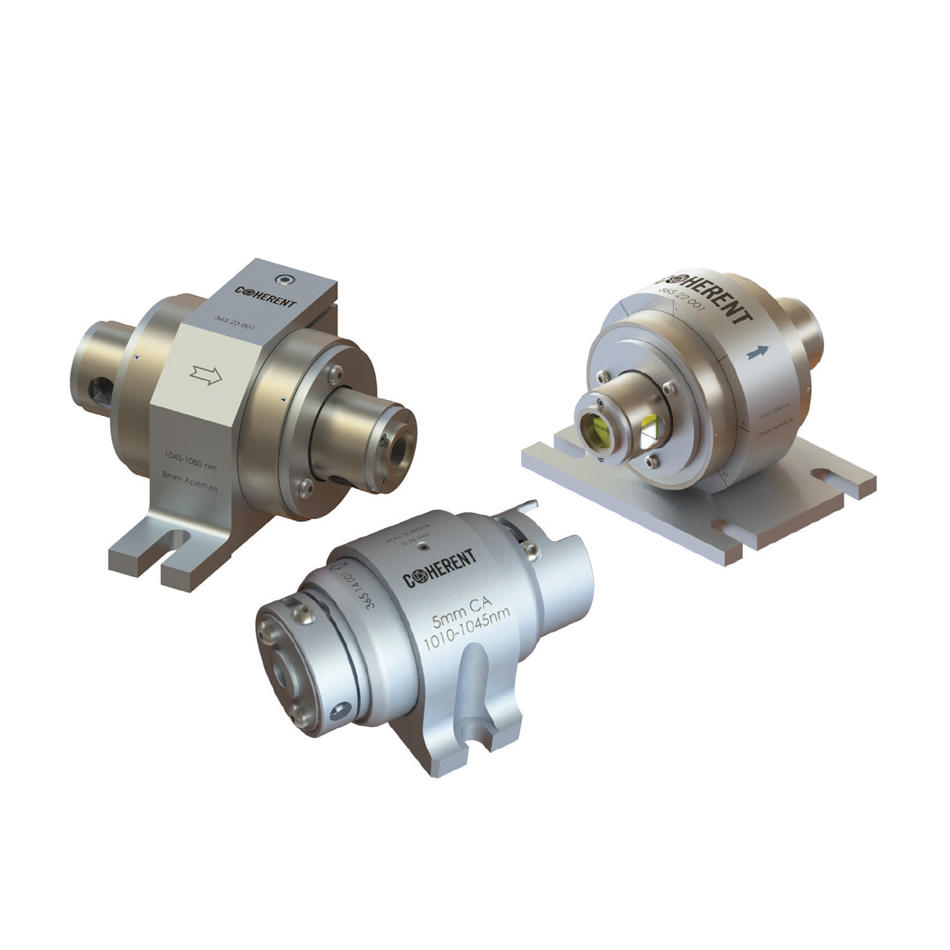

We are already using this new generation of higher-performance and reliability WGPs to improve the Faraday isolators we build for manufacturers of QCLs. Learn more about what Coherent wire grid polarizers can do for you.