Optics

Metrology

There are any number of parameters you can define for an optical or optomechanical product - including physical and optical specifications. But if you’ve specified it, then we measure it.

Intensive metrology ensures your products deliver a perfect fit and meet all optical specifications. We make sure that the coatings deliver the correct performance at every wavelength, and we measure LIDT wherever you specify. And we measure the alignment of every optomechanical assembly.

Key Capabilities

Physical Dimensions It’s simple but it’s also very important. We measure every specified dimensional detail using tried and true tools like calipers. |

Surface Shape Laser interferometry is used to confirm the shape accuracy (i.e., wavefront) of very reflective or transmissive optic. |

Laser-Induced Damage Threshold (LIDT) Determining the threshold for laser damage minimizes the chance you might damage your optics when using high power lasers. |

Spectrophotometry The performance of most coatings depends on the wavelength of the incident light and we use spectrophotometers to measure that. |

|

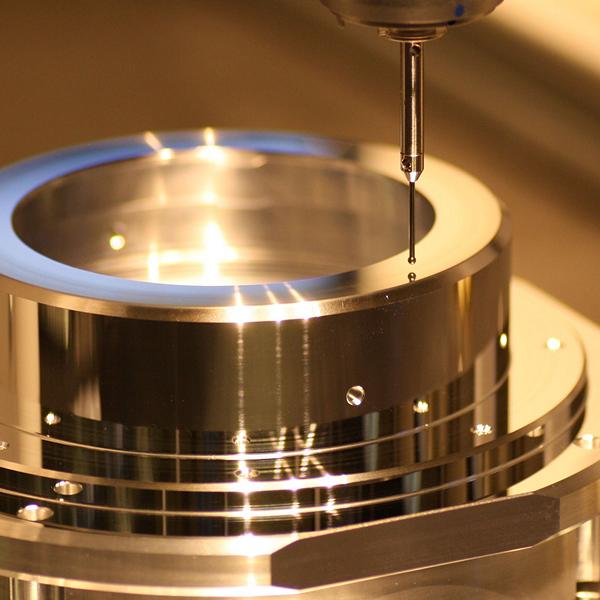

Surface Smoothness Unwanted surface roughness can cause scatter problems which is why we quantify surface roughness (Ra) using calibrated profilometers. |

Featured Blog

Coherent and NIF: Creating a Fusion Energy Source

Coherent custom optics are just one part of a huge laser system being used to produce nuclear fusion, the process which powers the sun.