HIGHVISION SPEEDS AND IMPROVES PRECISION FIBER LASER WELDING

Integrated machine vision system enables the most demanding remote welding applications in e-mobility manufacturing and automotive assembly.

October 24, 2022 by Coherent

HIGHvision is an advanced machine vision add-on for Coherent HIGHmotion 2D and RLSK remote laser welding heads that enables precision seam tracking and beam position control. It delivers increased throughput, together with exceptional quality and reliability, for welding of parts with complex 3D shapes or long seams involving curves. This makes it particularly useful for fillet welding of body-in-white and car doors, battery manufacturing processes such as can-cap sealing, and busbar and tab welding, as well as hairpin welding in electric motor production.

HIGHvision combines a camera, various illumination options, and software modules specifically optimized for the following four different types of tasks:

Seam Tracking: In fillet welding, the vision system detects differences in the actual part from the programmed seam position. It then automatically corrects laser beam position “on the fly.” Precise position correction can be achieved over the entire workspace at welding speeds of more than 10 m/min.

Position Matching: Advanced image-processing algorithms are used to recognize part orientation and identify misalignments. The software automatically corrects the programmed seam position to ensure optimal weld quality. The system can also recognize various part features, making it ideal for welding prismatic, cylindrical, and pouch-type batteries.

Shape Recognition: This adjusts beam position after recognizing and locating a user-defined shape on the part prior to welding. This translates into higher productivity because it relaxes the requirements on part positioning. There are virtually no limits to the types of user-defined shapes.

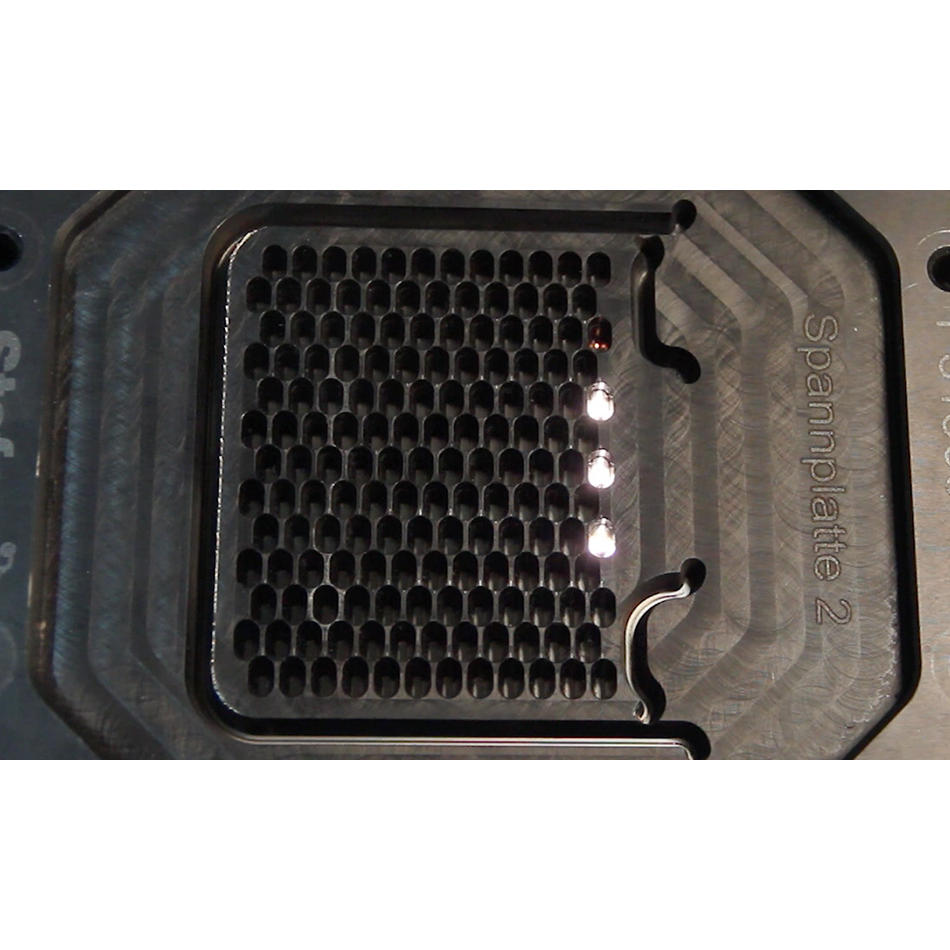

Hairpin Detection: This performs automatic detection of hairpins in just a few milliseconds, making it one of the fastest systems available on the market. Once the hairpin position and gap between adjacent parts is determined, the system automatically adjusts seam parameters to ensure the highest quality weld quality.

HIGHvision is among the fastest and most accurate solutions available because it’s an embedded vision system designed from the ground up specifically for integration with Coherent remote laser welding heads. Having a comprehensive understanding and control over every aspect of system optics, mechanics, and software-enabled Coherent engineers to thoroughly optimize the system in terms of performance, speed, ease of use, and reliability. Plus, it allows the customer the simplicity of working with a single vendor for process development and ongoing service and support.

Learn more about HIGHvision advanced machine vision systems.