Coherent HighLight Fiber Lasers Seal the Deal for Battery Manufacturers

Adjustable Ring Mode fiber lasers provide the operational flexibility for both high-speed scanner and gantry-type prismatic battery can-to-cap welding systems.

June 6, 2022 by Coherent

A major part of the effort to increase performance and lower cost for electric vehicles (EVs) is focused on improving battery technology. Virtually every aspect of battery design and production is being rethought in this process. For example, some groups are exploring new battery chemistries. The goal is to improve storage capacity, recharge speed, and lifetime, and also eliminate materials that are problematic to source or harmful to the environment.

Others are concentrating on battery manufacturing technology; specifically, developing methods and materials that simultaneously bring down fabrication costs (especially reducing production cycle time) and also extend reliability. Can-to-cap welding of prismatic battery cells is a standout example of this effort, and one in which recent developments by Coherent in laser welding offer substantial advantages.

It’s hard to keep a lid on battery welding

Can-to-cap welding specifically refers to the process of sealing the lid on the casing (can) which contains all the electrode structures for the battery. This sealing is done after those internal parts have been assembled into the can. Since this occurs near the end of the production cycle – after most of the value has been built into the assembly – scrapping parts at this stage is particularly costly.

The sealing operation requires making a fairly long, continuous weld. A typical prismatic battery is around 20 mm wide by 300 mm long, and the weld goes around the entire battery perimeter. The key things manufacturers want to achieve with their welding process are:

- A hermetic seal with no gaps along the entire weld – even if the original parts don’t fit together perfectly or consistently (especially at the corners)

- Adequate penetration depth and low weld porosity so that the weld is strong enough to last the lifetime of the battery without cracking open, even when subjected to vibration and mechanical shock

- No spattered metal, especially inside the battery where it might create electrical short circuits – spatter is especially a problem when welding aluminum because it melts at a low temperature and the melt pool can bubble

- Limited heat input into the battery to avoid damaging internal parts

Fiber lasers can deliver on all these requirements, and have already established themselves as excellent production tools for prismatic battery can-to-cap welding. In the most common implementation, the beam focusing optics are moved around on a “gantry” to follow the shape of the desired weld seam.

This gantry approach delivers really precise mechanical alignment and a highly consistent weld. This is because the laser beam always hits the work piece at the exact right place and at the same angle. The problem is that moving the optics (or alternately, the battery) over the relatively long weld seam required for a prismatic battery makes a gantry system slow. And, slower speed translates directly into higher production costs.

Powerful power control

It’s possible to weld prismatic batteries much faster by just moving the weightless laser beam using scanner mirrors. But this poses a couple of problems. First, the beam gets geometrically distorted as it approaches the limits of the field of view, changing from a circle to an oval. Because of the large size of these parts, this is especially problematic in the corners and ends of the cans. Second, this beam distortion can combine with the change in scan direction in the corners to produce a weld seam that doesn’t meet the customer’s quality requirements. Also, the changing beam size and angle of incidence on the part changes the power density at the work surface, which affects the way it welds.

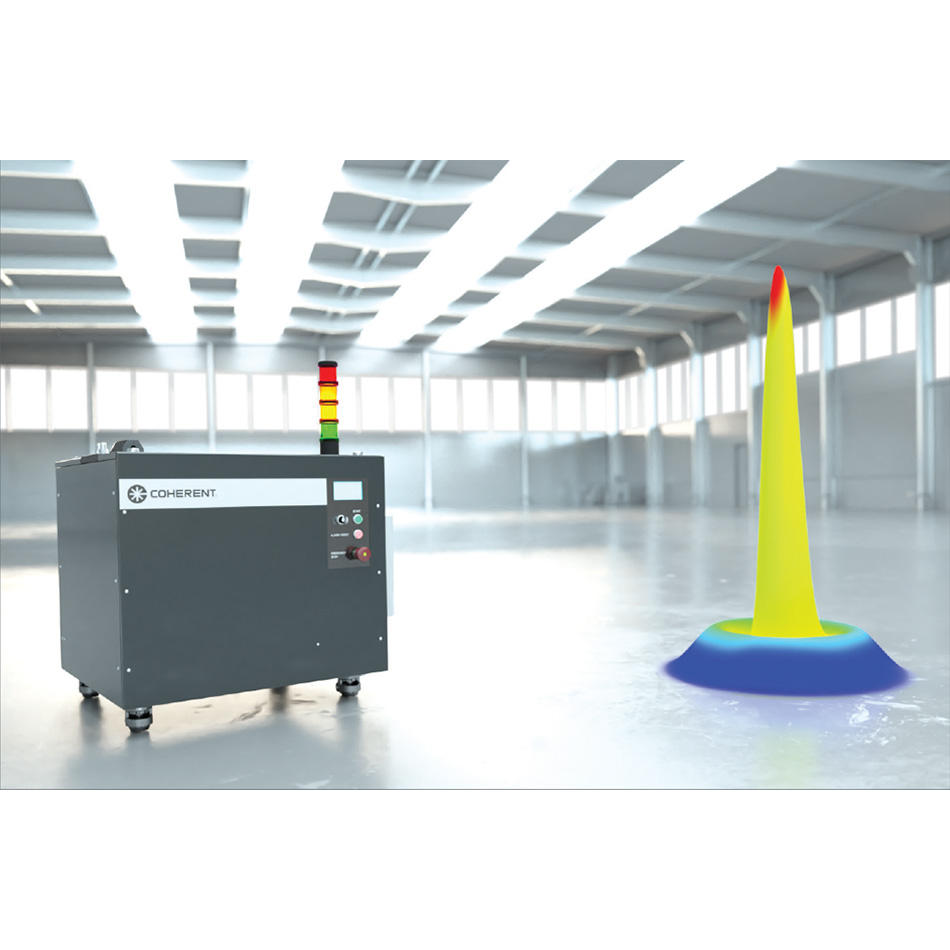

There was really no way to completely compensate for all these factors until Coherent introduced Adjustable Ring Mode fiber laser (ARM) technology. In our ARM FL fiber laser family, the beam isn’t just the traditional single spot. Instead, it’s a center spot with another concentric ring of laser light around it. The power in the center and ring spots can be independently controlled – on very rapid timescales. This gives highly dynamic control over exactly how the laser energy is spatially distributed during welding.

What this means is that the ARM laser can compensate for the way the spot gets distorted when approaching the outer limits of the scanning field of the scanner. Specifically, the power ratio of the center and ring beams can be changed on the fly to make the laser to consistently produce the same welding result, even where the spot gets elongated. And the overall power (and power ratio) can also be varied quickly enough to correct for changes in scanner speed – because the beam slows down when coming into the corner of the weld seam, and then speeds back up when coming out of the corner. Plus, this power modulation is performed under industry-leading, active, closed-loop control to ensure high process stability, consistency, and reproducibility.

The ARM laser also enables weld seam width and penetration depth to be independently controlled. This eliminates the need to maintain tight tolerances on part fit-up (gap width); lowering this tolerance reduces production costs. It also minimizes the heat-affected zone (HAZ), enables high-speed scanning (>350 mm/sec), and the ability to cover large scan fields.

All this overcomes the traditional tradeoff between speed and quality for fiber laser welding of prismatic batteries, and makes scanner welding systems a cost-effective, high-performance method for volume production. These same capabilities even make Coherent HighLight ARM fiber lasers a better option for traditional gantry-type welding systems, too.

Coherent delivers total welding solutions

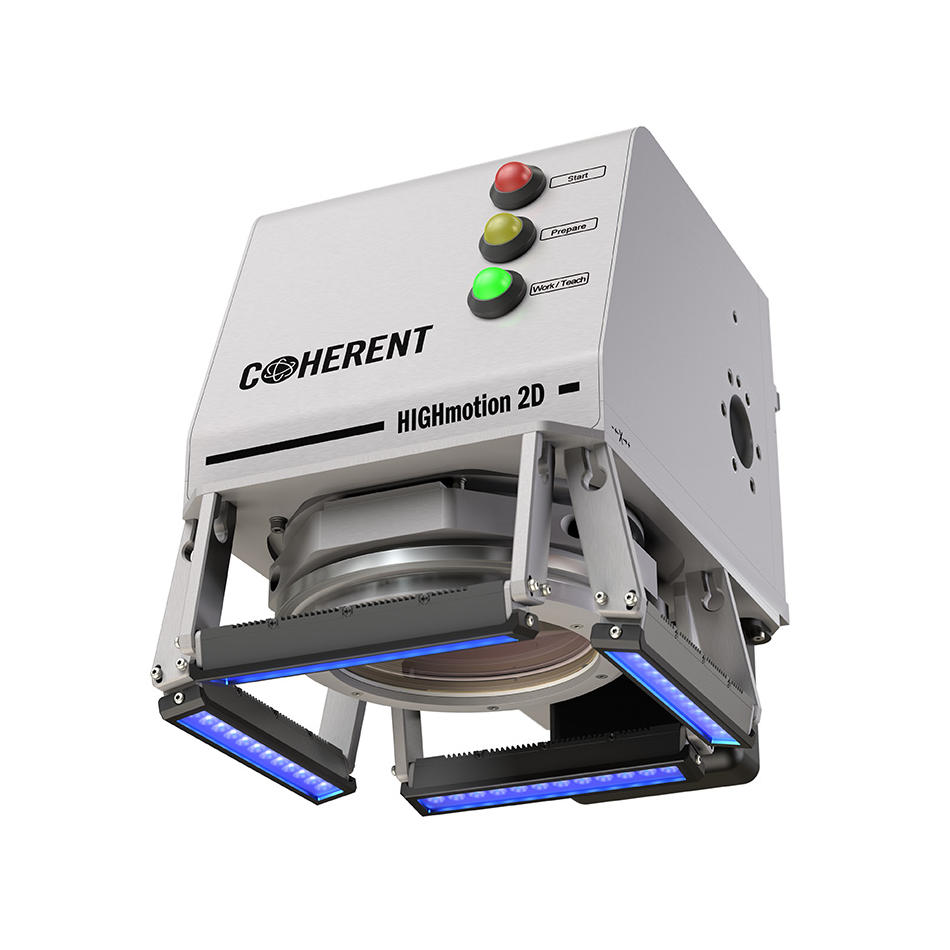

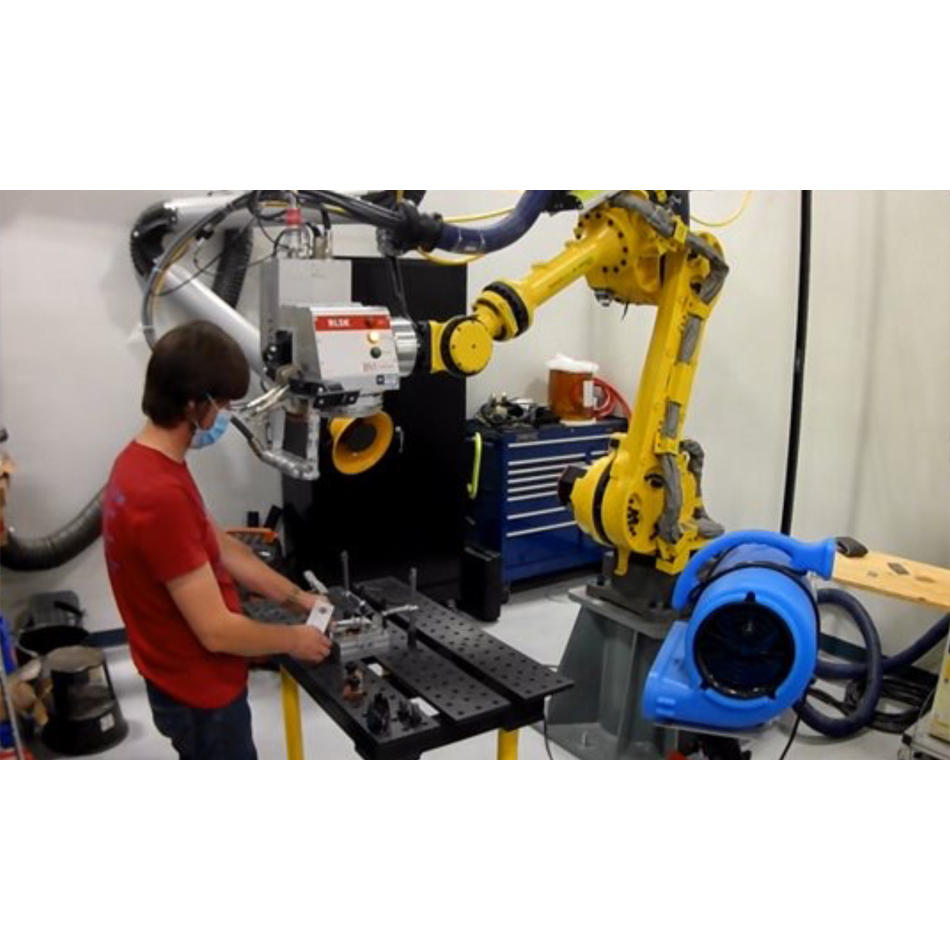

In today´s modern battery Gigafactories, bringing new equipment online quickly is just as challenging as the welding process itself. To ease implementation, we are able to offer more for battery can-to-cap welding than just Coherent HighLight ARM lasers alone. Combined with our HIGHmotion 2D or RLSK Scanners and Vision System HIGHvision we offer a complete integrated solution for your welding application. Additionally, scanner systems from major suppliers, are also compatible.

Our Coherent Labs team can configure your welding system, and even assist in developing process recipes. Make Coherent your single point of contact to make designing, using, and maintaining your laser welding process fast, easy, and hassle-free.

Learn more about how Coherent can deliver a welding solution for prismatic battery can-to-cap welding that gives you both high throughput and quality.

Ready to get started? Contact Coherent Sales.