New Coherent PowerLine E QS Models: Compact, Air-Cooled Green Lasers for Marking Applications

The compact, economical PowerLine E 6 QS (AC) and PowerLine E 12 QS (AC) laser marking sub-systems include an air-cooled green (532 nm) laser, optional scanning optics, and power monitoring, for marking applications in the semiconductor and electronics industries.

May 17, 2022 by Coherent

From the Coherent PowerLine family, our newest laser markers extend the popular air-cooled PowerLine E series from the infrared to green wavelengths.

The cool thing about green lasers

Green laser light is often an optimum match for marking semiconductors and plastics, compared to infrared lasers. The high absorption in this wavelength domain results in high-quality, clean marks with minimized risk of thermal damage to underlying circuitry components. However, green lasers are more sensitive to temperature changes than IR lasers and often require a chiller (i.e., water cooling) as a result. This need for a chiller increases both the cost and the carbon footprint of laser markers using these lasers.

The PowerLine E 6 QS (AC) and PowerLine E 12 QS (AC) laser markers now avoid this trade-off by offering a choice of either 6 or 12 watts of pulsed (Q-switched) output at a wavelength of 532 nm, in a completely air-cooled format. In addition to the elimination of water and reduced number of sub-components, the PowerLine E 6/12 QS (AC) is easier to integrate, maintain, and service than typical water-cooled laser markers.

The PowerLine E 12 QS (AC) is also available in our popular PowerLine D format where 1 laser powers two scanners, by means of a beamsplitter. This configuration enables larger marking fields and up to 2X faster marking, all while operating as a single laser marker.

For system builders and production line integration

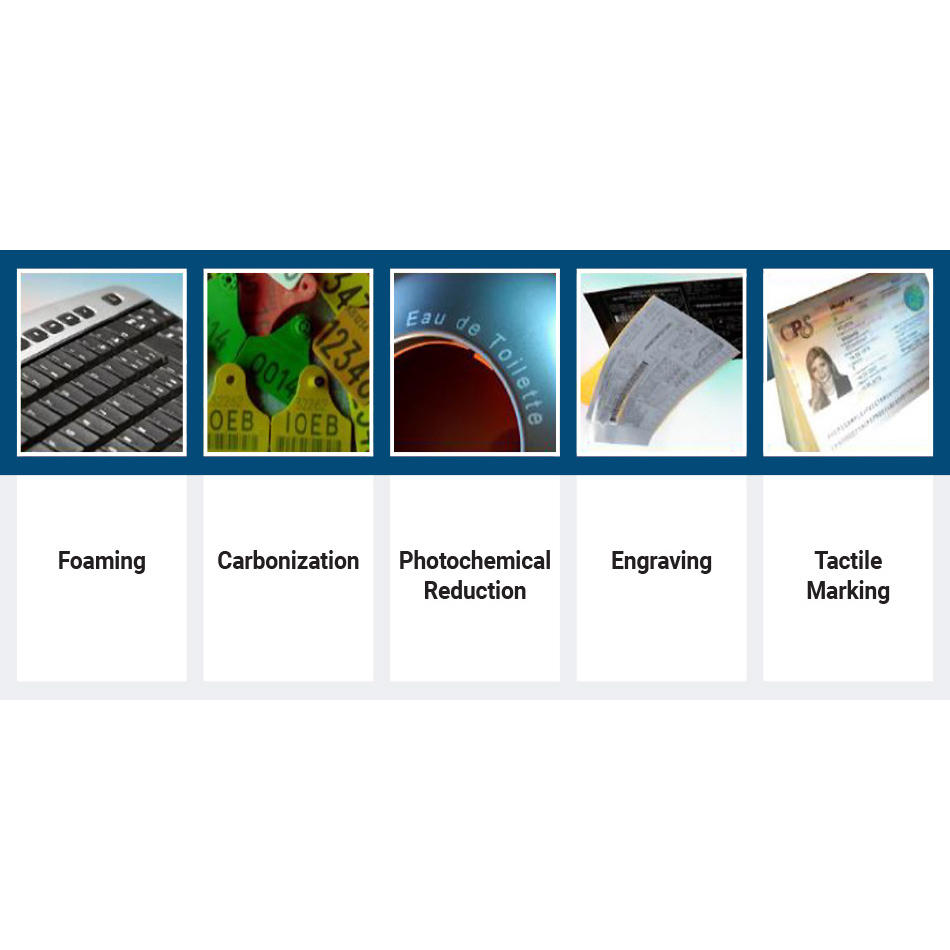

PowerLine laser markers are ideal for system builders and production line integration in any application where mark quality, aesthetics, and legibility are critical. Our flexible Visual Laser Marker (VLM) software allows straightforward implementation of complex tasks such as 3D marking on curved surfaces, on-the-fly marking, and mark serialization.

Just as important, our global service support structure, comprehensive service contracts, and local parts warehouses mean less downtime and higher overall throughput no matter where your marking application is located.

Learn more about the new PowerLine E QS laser markers and the PowerLine family of lasers.

Related Resources