Lower Costs with Automated Precision Marking of MDM Components

The combination of tray loading and machine vision delivers high volume and low cost.

July 07, 2022 by Coherent

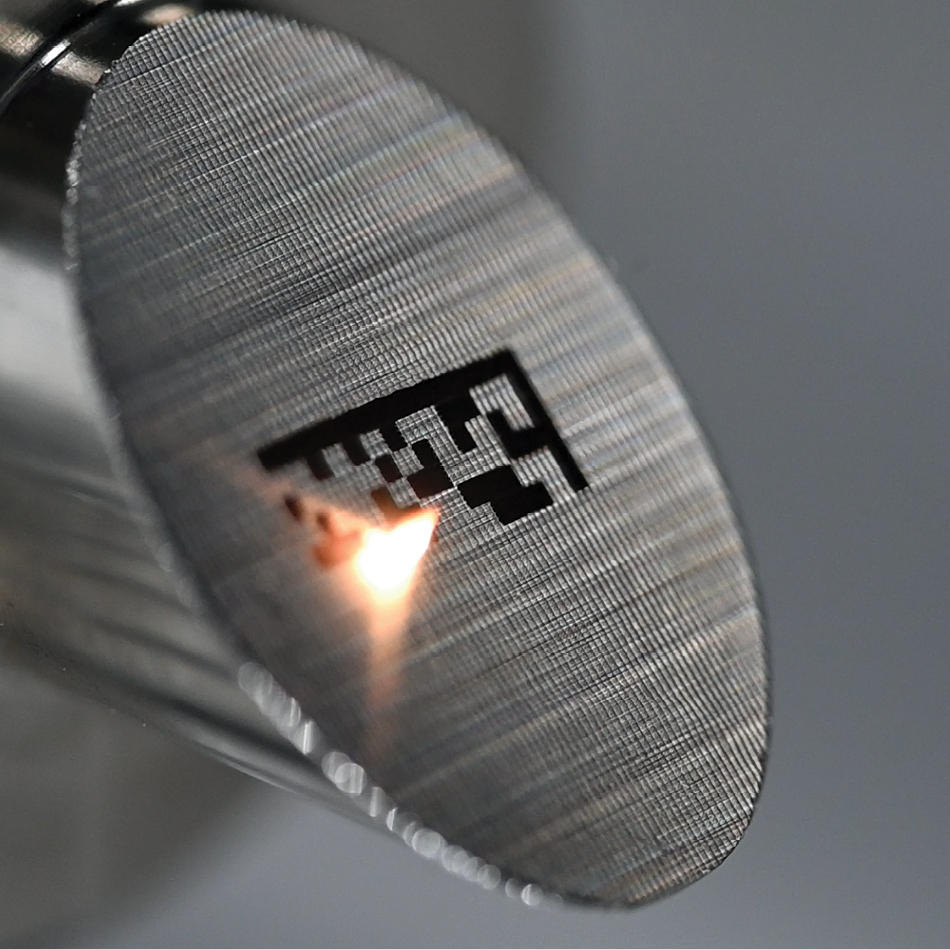

Most medical devices and components need to be permanently marked. Manual and semi-automated marking is widely used by contract manufacturers in the medical device manufacturing (MDM) industry which often includes modest volumes or high-value parts. But what about marking small components in higher volumes, moreover what if they’re commodity devices and components that cannot support the cost to create precision and/or highly detailed marks in this way? Completely automating the marking process using marking machines with tray handling and integrated machine vision now offers a very cost-effective solution.

Making a mark in MDM

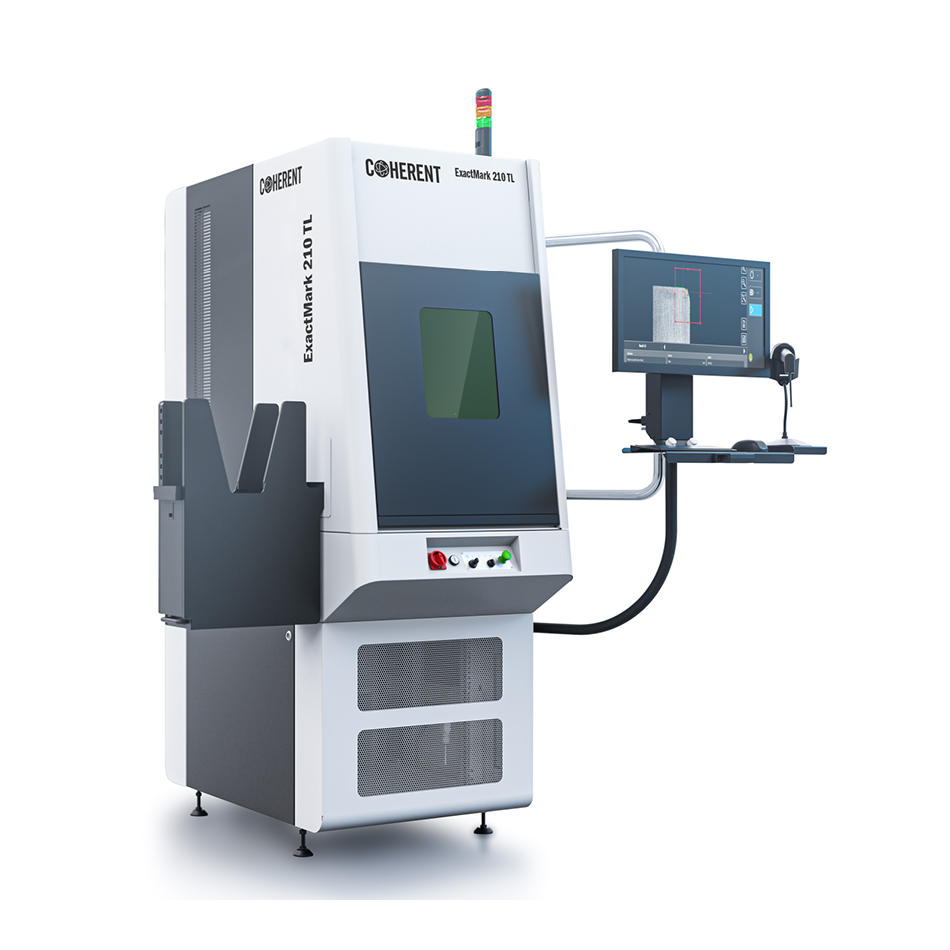

The Coherent ExactMark family of laser marking machines was recently extended to offer this type of economic marking to MDM and other industries with similar small size/high volume challenges. These machines are available with a choice of several different fibers and solid-state lasers, providing infrared, green, or UV outputs. This broad laser choice means just about any metal or plastic used in devices and disposables can be marked with one of these machines with a wavelength that maximizes mark contrast and avoids unwanted thermal charring or melting.

The machine optics are optimized for marking field sizes to match standard trays, both magazine and stack-type (e.g., JEDEC). As many as 30 trays can be pre-loaded for marking in a single unattended run. The use of PartVision (a through-the-lens vision system) in these machines simplifies automated part alignment and even post-inspection. An optional barcode scanner further streamlines the marking process. Operator subjectivity is simply no longer part of the marking process. This all results in lower labor costs, lower cost-per-mark, and higher marking yields.

Powerful, productive software

All ExactMark machines come with Coherent Laser Framework, an easy-to-use software suite that simplifies job setup, operation, inspection, and data logging, all through a single intuitive user experience. Laser FrameWork also enables easy integration into the modern production setting with numerous communication interfaces and protocols.