Coherent Expands Laser Welding Solutions

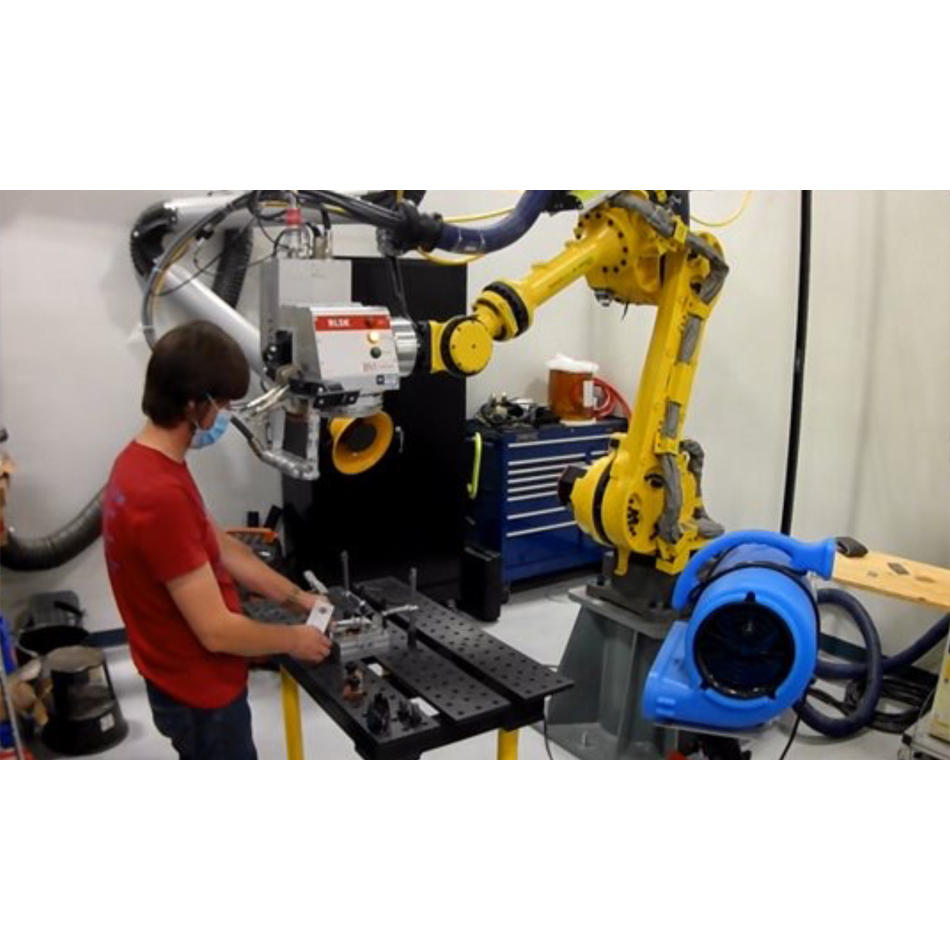

Coherent can now integrate Precitec processing heads and process monitoring tools in ARM fiber laser welding systems for e-mobility manufacturing.

March 08, 2022 by Coherent

Coherent and Precitec now make advanced fiber laser welding technology easier to put into production, particularly for demanding applications in e-mobility. Specifically, Coherent will offer Precitec processing heads, process monitoring systems, and remote welding products in the portfolio of components available for integration with our HighLight ARM fiber lasers.

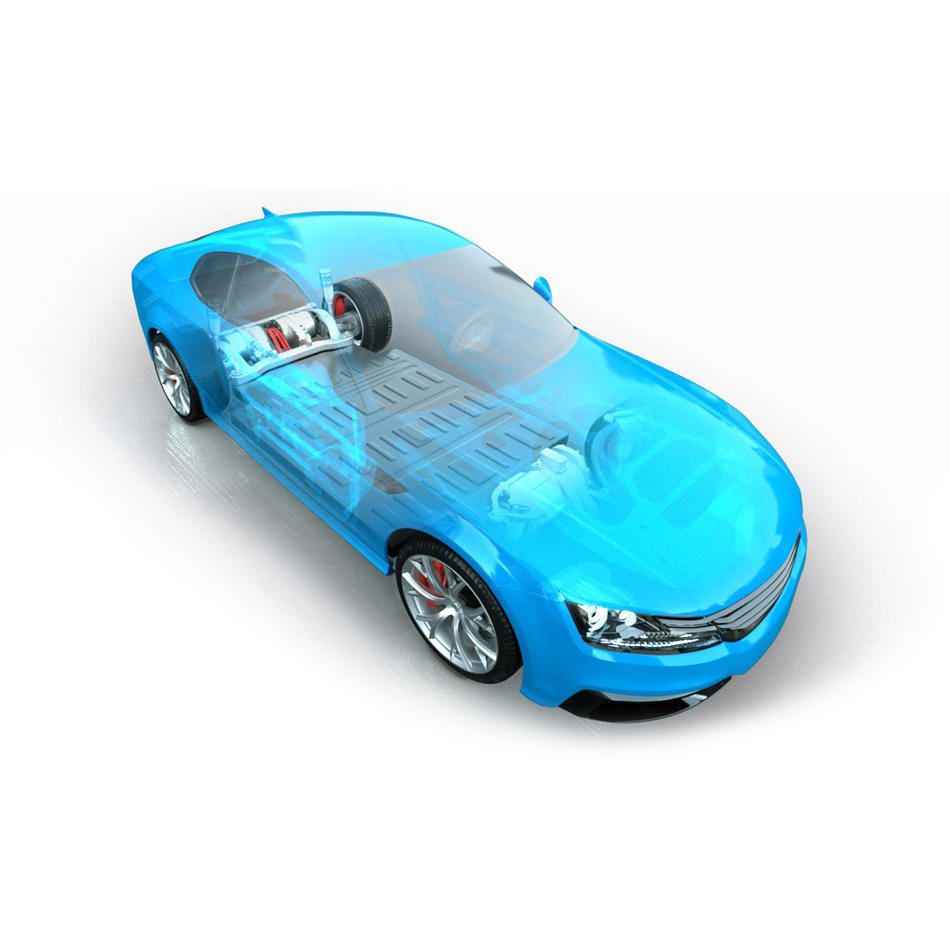

EVs heat up the demand for precision laser welding

An integrated approach is necessary to successfully address the increasingly complex and sensitive welding processes now being brought online, particularly in e-mobility production. Examples of these include various steps in battery production, like can/cap welding, joining dissimilar materials, and foil welding, as well as other EV production tasks like hairpin (motor stator) welding, and busbar welding.

We developed adjustable ring mode (ARM) laser technology specifically to service this need. ARM technology enables unmatched spatial and temporal control over how laser energy is delivered to the workpiece. This is essential for welding thin, heat-sensitive, or otherwise delicate parts without damaging them, and for achieving consistent control over weld seam width and penetration depth. The precisely controlled laser beam has to be focused on the workpiece by the processing head. And this has to be done in a way that preserves the quality of the beam, and also provides the ability to move the beam around to follow the desired weld path.

Coherent puts laser welding together

Coherent offers complete welding solutions including the laser, process head, and control software and electronics. By supplying the entire package, we can ensure that all the various parts of the system work in concert so just the right amount of laser energy is consistently delivered to the proper location on the workpiece, exactly when it’s needed. Plus, this eliminates the need for the user to become a laser expert and engineer all this themselves.

Coherent can integrate processing heads from a range of manufacturers. One particular advantage of the Precitec products is their process monitoring modules. These perform continuous monitoring of multiple process parameters in real-time enabling production errors to be immediately detected, and even corrected, on the fly. For example, Precitec offers a sensor that utilizes optical coherence tomography (OCT) to monitor weld penetration depth. The process sensors also log data for traceability purposes.

Combining Precitec modular laser welding optics and automated process monitoring tools, together with Coherent ARM fiber laser systems, deliver customers a complete and reliable solution. And, providing them as a single, integrated solution streamlines and speeds every part of the process – identifying the right combination of hardware, developing the optimum process parameters, installing the equipment, getting production running, and then supporting it long term. This is the fastest and most cost-effective way of bringing the unique benefits of ARM fiber laser welding into production for the most demanding e-mobility applications.

Related Resources