Electronics Manufacturing

Perform fast, high-precision cutting, welding, marking, and ablation of metals and plastics with laser sources and systems.

- Integration-Ready Get up and running quicker with tools that integrate easily into your production.

- User Friendly Maximize productivity and reduce operator training with simple, intuitive HMIs.

- Cost-Effective Improve yields and reduce cost per part with consistent, reliable laser tools.

Laser Welding

Quickly produce small, strong, cosmetically attractive welds with minimal heat affected zone for pressure sensors, batteries, mobile devices, and other products.

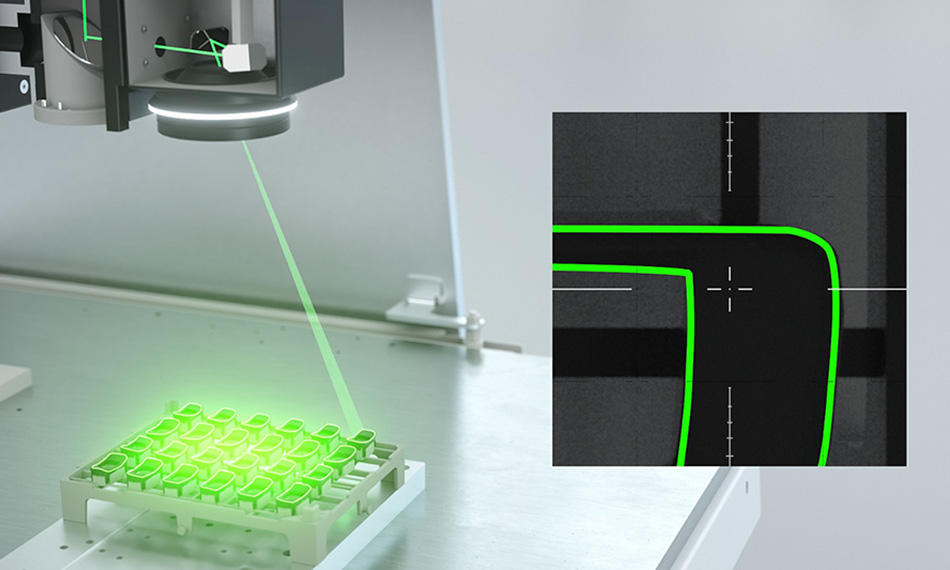

Laser Cutting

Rapidly cut simple and complex contours, even in multilayer and composite materials, plus foils, with better and more consistent results than water jets and blades.

Laser Marking

Write high-contrast serial numbers, product identifiers, traceability codes, logos, Datamatrix codes, and more on plastics, composites, metals, ceramics, and paper.

Laser Ablation

Swiftly strip insulation or remove virtually any material with precise and consistent depth control, and without any heat damage to the underlying product.

Video Spotlight

Laser FrameWork Makes a Mark in Siemens' Digital Factory

The ID Link is an important step toward the digital product label. Laser-marking this ID Link as a standardized code on devices is a challenge. It requires a digital end-to-end solution from development to production. Positioning accuracy and quality are important. The Coherent PowerLine E is the ideal solution for @Siemens. Above all, its software suite, Laser FrameWork, is crucial for integration into Siemens' digital factory and communication with Siemens' internal IT systems. The integrated vision system gives Siemens a complete solution from a single source.

Featured Blog

How Lasers Marking Works

Did you know that today you are surrounded by things large and small that have been permanently marked with a laser? From the SIM card in your phone to the milk container in your refrigerator and the control panel of your washing machine, laser marking is everywhere. Read why and how lasers make all these different marks.

Featured White Paper

New Laser-Based PCB Depaneling Method

Technological changes in the materials, thickness, and composition of PCBs are motivating a move away from traditional mechanical cutting and depaneling methods towards laser-based processes.

Global Customers

Ready to Get Started?

Share your contact info and a specialist will reach out.

Shop Coherent

Online shopping for lasers, optical fibers, power meters and sensors, accessories, and much more on Coherent online has never been easier.