Rare Elements Bring New Capabilities to Optical Fiber

From surgery to space, lasers using doped fiber are used in every-day technologies.

March 14, 2023 by Coherent

Optical fiber is everywhere — our home internet, automobiles, medical offices, telecommunications, and many more, all employ optical fiber to deliver services we rely on.

Today, specialty optical fibers bring collision avoidance to your car, precision surgery with minimal scarring, diagnose eye diseases, and can remotely sense temperature changes in power plants, or physical strain in large bridges. In many of these applications, the fiber has replaced copper wire because it offers higher data rates and/or lower weight.

It all started when engineers realized that light could be efficiently sent down an optical fiber: a thin strand of glass.

There are many different types of optical fiber needed for these diverse applications. The fibers that are not used for telecom transmission are often collectively referred to as “specialty fibers”.

In terms of its broad impact across many industries and technologies, one of the most important applications of specialty fibers is their use in generating laser light and amplifying laser light.

This specialization is usually implemented by a rare earth element. The glass contains a small amount of one or more of these elements. The use of rare earth dopants brings greater precision and control over the wavelength and power required across the variety of applications that rely on specialty optical fiber.

The growing demand for specialty optical fiber

Rare earths are a group of metal elements including neodymium (Nd), erbium (Er), thulium (Tm), holmium (Ho), and ytterbium (Yb).

Fibers doped with rare earth metals act as the gain medium in lasers optimized for industrial, scientific, medical, and aerospace applications.

The diverse end uses of these lasers range from welding “difficult” metals in e-vehicles, to precision laser surgery, to marking medical devices, to remote imaging.

Coherent is a world-leading manufacturer of this type of specialty optical fiber, supporting the ever-growing demand with over 11,000 km (6,835 mi) of fiber a year - more than the distance from the North Pole to the equator!

Traditional solid-state lasers and the heat problem

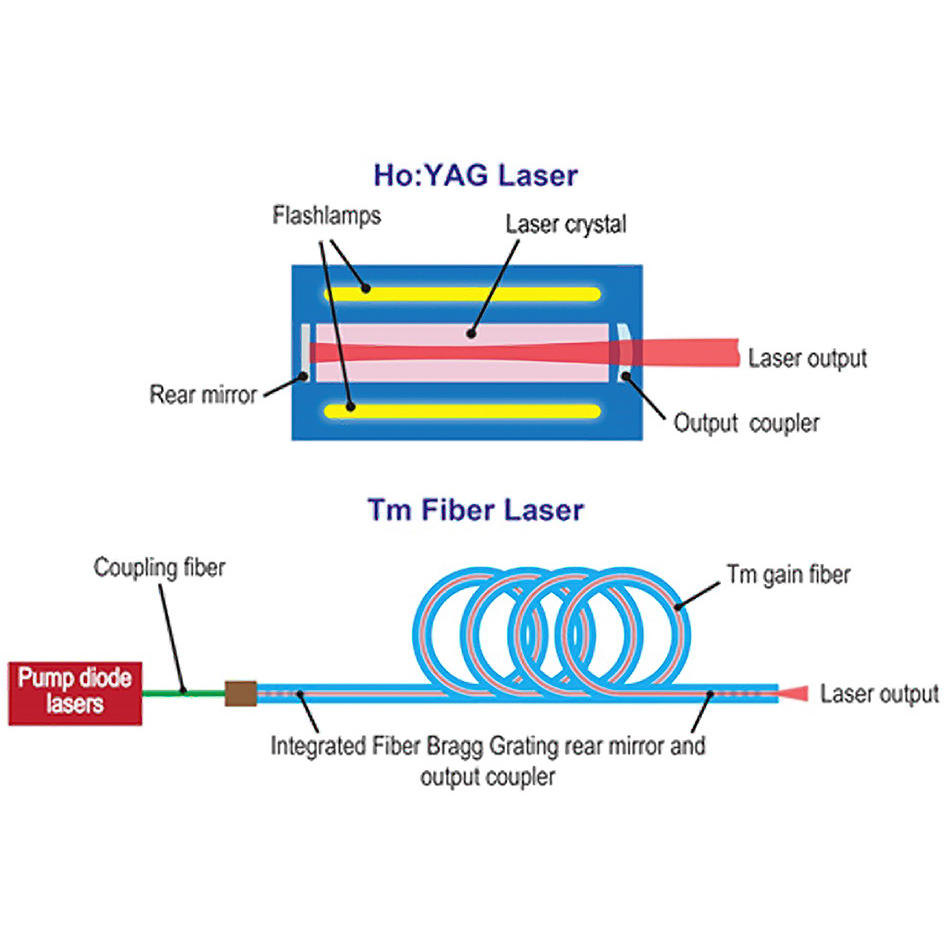

Neodymium in particular has actually been used for decades in lasers.

In the early days of lasers, scientists found that when neodymium ions are hosted in glass or certain crystal materials such as garnet or vanadate, the doped material can absorb light and then re-emit the energy as intense laser light. The absorption is called “pumping” and for years the pump light was provided by intense flash lamps.

To reduce problematic waste heat produced in these lasers, Coherent and other laser manufacturers replaced the lamps with semiconductor (diode-laser) chips to create the diode-pumped solid-state (DPSS) laser.

But while the heat was reduced, it was certainly not eliminated. And heat still had to flow from the middle of the crystal to the surrounding cooling water.

Then the field of telecom pointed to an innovative solution.

Fiber – the shape of things to come

Because in the world of long-distance telecom based on optical fibers, engineers had meanwhile found there was another – apparently unrelated – photonic technological challenge to overcome. Long distance, i.e., trans-oceanic, transmission was a problem because of limits to how far the light signal could go down a fiber before the small losses eventually killed it.

A solution came in 1987 in the form of the erbium-doped fiber amplifier (EDFA).

Engineers showed that a fiber doped with erbium ions could absorb light from a diode laser and act as a laser amplifier. Specifically, the EDFA directly boosts (amplifies) any light signal passing along the fiber. This all-optical signal amplification has proved key to the digitally connected global world we live in today.

Fiber lasers and amplifiers

The fiber laser amplifier also showed laser engineers a pathway to higher-power lasers for scientific and industrial applications - without all the cooling problems. A range of specialty fibers based on the same type of rare earth doping was soon developed and these were used to create fiber lasers and high-power amplifiers. With power ranging from a few watts to kilowatts, these fiber-based laser systems now support an incredibly diverse world of applications, including efficient materials processing applications such as drilling, cutting, welding, and marking. In fact, fiber lasers dominate some of these applications.

Figure 1. (above) shows the spectrum of visible, infrared, and eye-safe wavelengths.

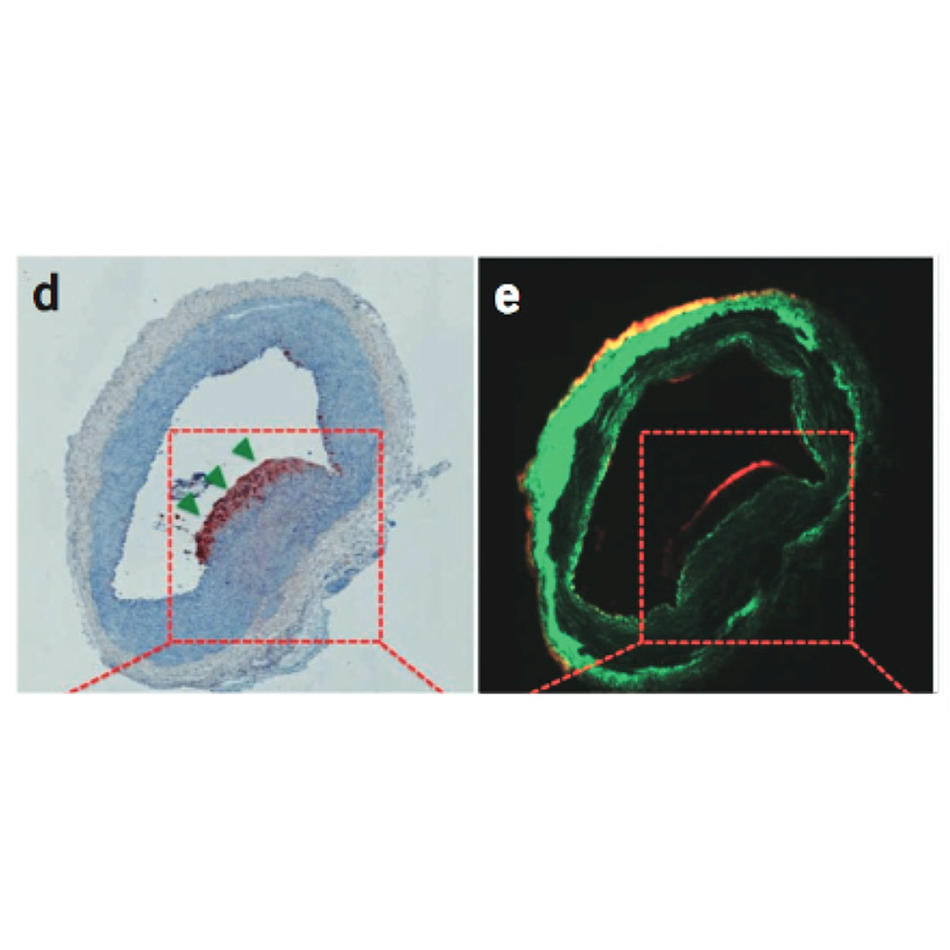

Another area of fiber laser domination is in medical applications. Thulium-doped fibers are widely used in urology and lithotripsy treatment, as the Tm fiber laser produces higher pulse rates, resulting in smaller stone fragments and thereby reducing patient discomfort and speeding recovery.

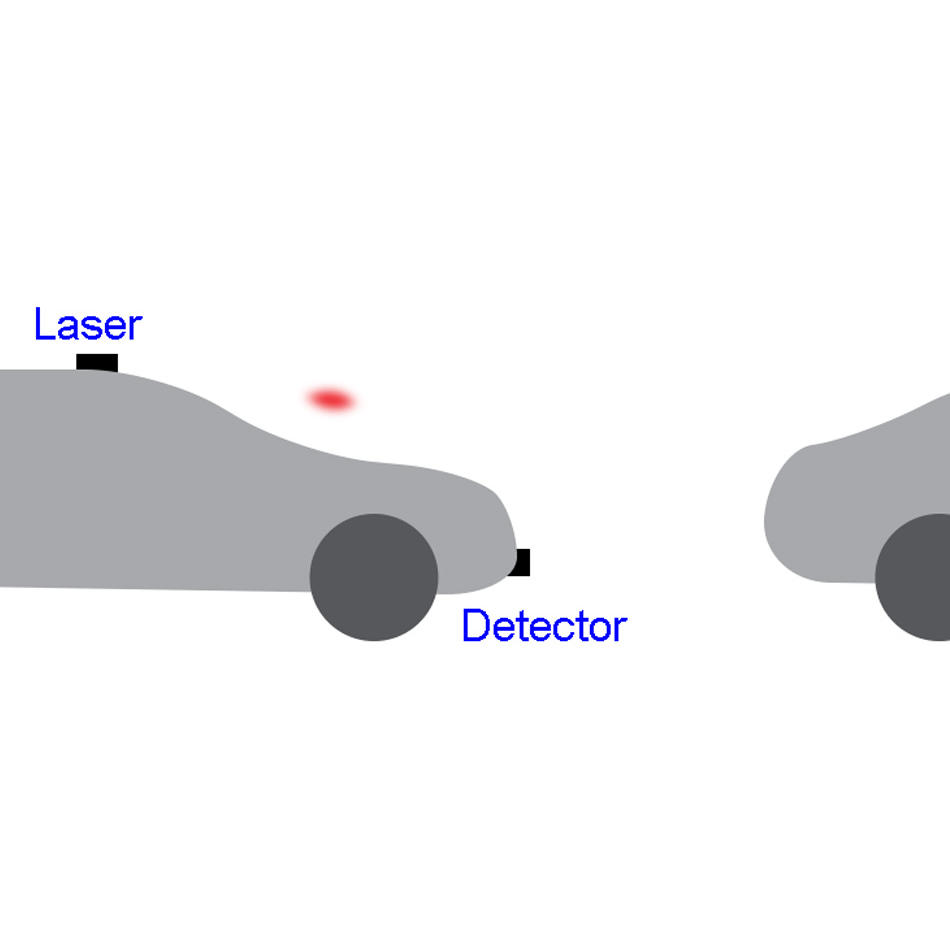

The onset of strong light absorption by water at wavelengths around 1400 nm make wavelengths longer than this useful for medical (e.g., surgical ablation) applications while enabling remote fiber delivery. Because of this water absorption, 1400 nm is generally regarded as the cut-on wavelength for eye-safe lasers; longer wavelengths are safely absorbed by water on the outside of the eye and don’t penetrate to the retina. This makes these invisible wavelengths also useful in innovative applications such as lidar imaging, automotive safety systems, and autonomous (self-driving) cars for example.

Thousands of different doped fiber options

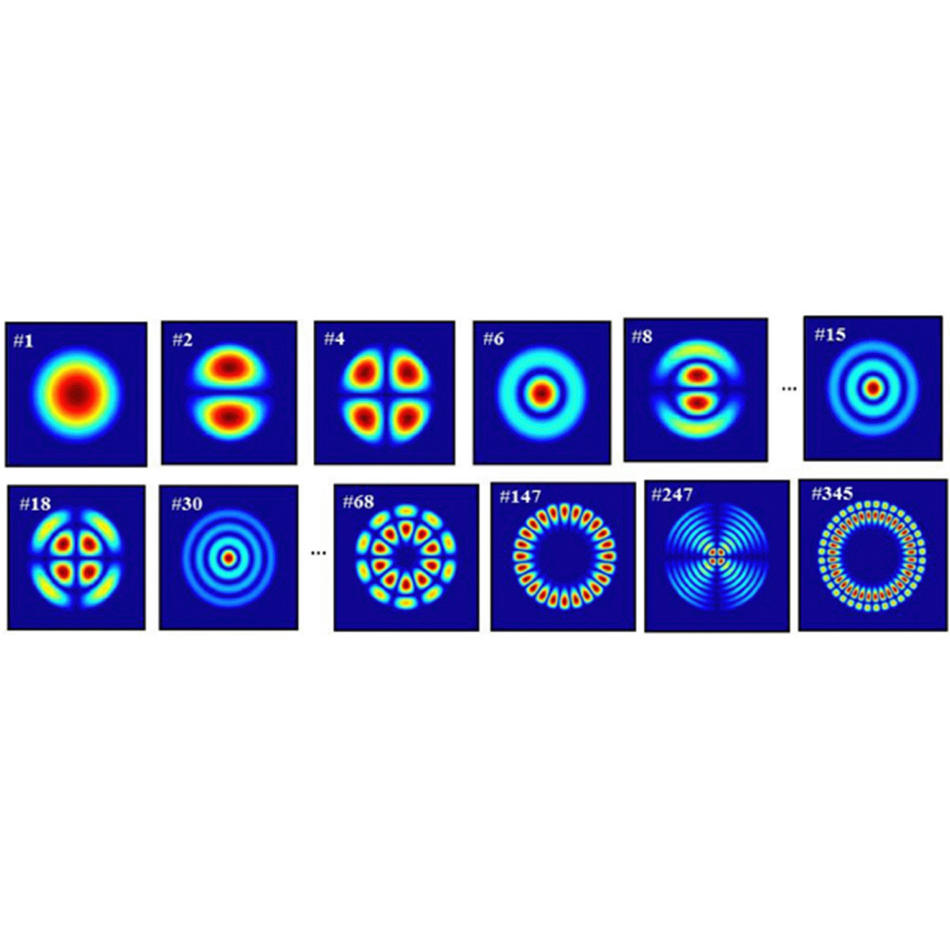

Figure 2 summarizes the wavelength characteristics of the five commonly used rare earth ions Nd, Er, Yb, Tm, or Ho: both the emission wavelengths and the requisite pumping wavelengths. Yb is increasingly popular in ultra-short pulse (USP) lasers because its relatively broad emission bandwidth supports mode-locked fiber lasers with pulses as short as 50 femtoseconds and amplified (i.e., high power) systems like the Coherent Monaco series with pulses of just a few hundred femtoseconds (fs).

The wavelength characteristics of the five commonly used rare earth ions Nd, Er, Yb, Tm, and Ho. The red curve shows the attenuation of the glass host used in the fiber.

In addition to the five individual dopants, Coherent also offers specialty optical fiber co-doped with both Er and Yb. The Er acts as the gain medium, resulting in emission around 1550 nm, depending on the doping concentration. The Yb acts as a light absorber, preventing unwanted amplified spontaneous emission around 1 micron, ensuring a laser system that is completely eye safe.

Coherent doped fibers are available as single-mode (SM), multi-mode (MM), polarization maintaining (PM), and large area-mode (LMA) fibers, all with several choices in both the numerical aperture (NA) and the core diameter. Plus, the full product line includes single-clad, double-clad, and triple-clad fibers. Altogether this encompasses thousands of different doped fibers. And on top of all that, we also make custom fibers that can withstand high heat, assist with aircraft navigation, aid with satellite communications, and much more.

Not-so-rare earths

The story of doped fiber and its use in lasers and laser amplifiers is one that combined clever engineers with a slice of good fortune, where a solution to one challenge proved ideal for another problem. The result has been an important power-scalable laser architecture all supported by doping with those not-so-rare earths.

Interested in buying your own specialty fiber? Visit us at shop.coherent.com/