Enabling Advanced Thermal Management Solutions

From lasers to electric vehicles, Coherent has the coolest materials and systems for thermal management.

September 21, 2023 by Coherent

Cooling has now become a very hot topic.

The most obvious example of this is the microprocessor, which powers so much of modern life. As the number of transistors contained on a chip has steadily increased, so has the amount of heat generated. And, most importantly, this heat is produced over much smaller areas on newer devices because of their increased miniaturization and higher density.

High-performance computation starts at the semiconductor level, which is the interface of conductors and insulators that control the flow of electrical current and form the building blocks of all modern electronics.

However, the continuous demand to enhance the performance has created thermal implications due to high power dissipation. Managing power dissipation is a critical factor in determining their speed, efficiency, and reliability. Having a robust thermal management solution is therefore imperative for optimizing performance and increasing the service lifetime of these components.

We call it “thermal management” – which means the tools and technologies used to maintain a system within its operating temperature range – because the requirements in many applications are more involved than simply lowering the temperature of something.

It's Getting Hotter Everywhere

But the need for innovative thermal management technology extends far beyond microelectronics.

Very few product categories are immune to the physical consequences of ineffective thermal management. Transportation, semiconductor manufacturing, information technology, life sciences, consumer electronics, and many more are increasingly dependent on innovative approaches to thermal management. The only material difference in the requirements for any of these markets is the magnitude of power dissipation.

Battery electric vehicle (BEV) traction inverters are a great example to focus on. Inverters convert DC electricity delivered from a battery to three-phase AC power required by the traction motor that propels the vehicle. The inverters and motors are designed to be highly efficient with more than 90% of the electrical energy drawn from the battery converted into mechanical energy to move the vehicle. The lost energy does not simply disappear, it is converted into heat.

Power inverters in BEVs are a prime example of the scale problem in modern thermal management. Inverters and motors move kilowatts per hour (kWh) and even single-digit gains as a result of superior thermal management add up to big savings over the short and long term. This can translate into a competitive advantage of several levels, including range lifetime, and engineering simplicity. And this translates to a lower bill of materials cost.

Another application is semiconductor process equipment – the tools used to fabricate microelectronic devices. This is necessary to maintain precise, reliable, and repeatable manufacturing processes. Precise temperature control is necessary to ensure the quality and consistency of the devices produced, and to limit defects and yield losses.

Thermal Management Leadership

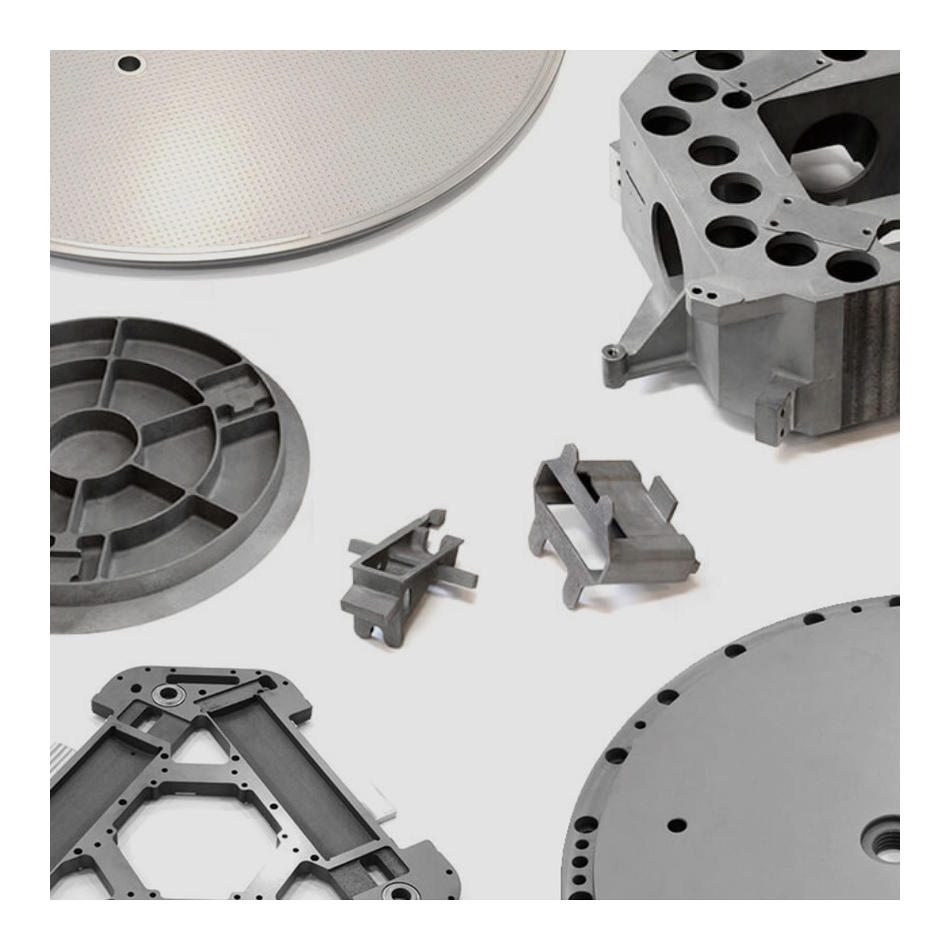

Coherent is a world leader in innovative engineered materials and sub-systems for thermal management, offering a broad portfolio that includes:

Reaction-Bonded Si/SiC Materials

RB-SiC offers a unique combination of physical characteristics, including high-temperature resistance, low coefficient of thermal expansion, chemical inertness, high strength, and high strength-to-weight ratio.

For applications where high-purity and temperature resistance is required, we manufacture RB-SiC components of nearly any size or shape, customized as needed, including high flatness, large infiltration depth, and internal cooling channels.

Applications: Semiconductor manufacturing, electric vehicles (EV), and life sciences instrumentation.

AI/SiC Metal Matrix Composites (MMC)

AI/SiC Metal Matrix Composites (MMC) offer a unique mix of high specific stiffness and high thermal stability.

Our range of composites can be cast into structures over 2 m x 2 m in size.

Applications: Semiconductor manufacturing, electric vehicles (EV), and life sciences instrumentation.

CVD Diamond

Diamond offers the highest thermal conductivity of any material, along with extraordinary hardness and high resistance to thermal shock.

We have capabilities for diamond growth (Microwave Plasma CVD), Laser Cutting, Lapping, Polishing, Grinding, Laser Marking, and Coatings and can supply CVD diamond material in sizes up to 145 mm diameter and 2 mm thickness, and can achieve a thermal conductivity of over 2200 W/m-K.

Applications: Datacom/Telecom, semiconductor manufacturing, and life sciences instrumentation.

Single Crystal SiC

The key advantages of SiC-based electronics of traditional Si include reduced switching losses, higher power density, better heat dissipation, and increased bandwidth capability.

We can grow low-defect 6H (semi-insulating) and 4H (conductive) SiC carbide wafers of up to 200 mm diameter in high volume.

Applications: Datacom/Telecom, semiconductor manufacturing, electric vehicles (EV), and life sciences instrumentation.

Thermoelectric Coolers (TECs)

TECs are solid-state refrigerators, which offer the advantage of active cooling with no moving parts, and high operational reliability.

Coherent TECs range from simple, single-stage coolers to complete chiller subsystems.

Applications: Datacom/Telecom, electric vehicles (EV), and life sciences instrumentation.

With such extensive and diverse capabilities, we are uniquely positioned to deliver thermal management solutions that ideally match the performance and cost requirements of your particular application.

Pretty cool, right?

Learn more about Coherent Engineered Materials and Coherent Wide Bandgap Electronics.